| Parameter | Specification |

| Material | LiTaO3 wafers(White or Black &Fe doped) |

| Diameter | 3inch/4inch/6inch |

| Diameter Tolerance | ±0.03mm |

| Curie Temp | 603±2℃ |

| Cutting Angle | X/Y/Z/X112Y/Y36/Y42/Y48/etc |

| Tol(±) | <0.20 mm |

| Thickness | 0.18 ~ 0.5mm or more |

| Primary Flat | 22mm /32mm /42.5mm /57.5mm |

| LTV (5mmx5mm) | <1µm |

| TTV | <3µm |

| BOW | -30 |

| WARP | <40µm |

| PLTV(<0.5um) | ≥95%(5mm*5mm) |

| Orientation Flat | All available |

| Surface Type | Single Side Polished(SSP) /Double Sides Polished(DSP) |

| Polished side Ra | <0.5nm |

| Back Side Criteria | General is 0.2-0.5µm or as customized |

| Edge Criteria | R=0.2mm or Bullnose |

| Fe doped | Fe doped for saw grade LN< wafers |

| Wafer Surface Criteria | |

| Contamination None | |

| Particles @>0.3 µm ≤30 | |

| Scratch , Chipping None | |

| Defect No edge cracks, scratches, saw marks, stains | |

| Packing | 25pcs per box |

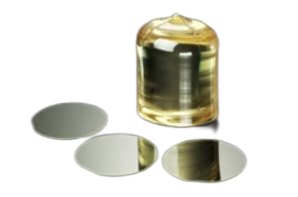

Optical Grade Lithium Tantalate Wafers

| Parameter | Specification |

| Material | LiTaO3 wafers(White or Black) |

| Diameter | 2inch/3inch/4inch |

| Diameter Tolerance | ±0.03mm |

| Curie Temp | 603±2℃ |

| Cutting Angle | X/Y/Z etc. |

| Tol(±) | <0.20 mm |

| Thickness | 0.18 ~ 0.5mm or more |

| Primary Flat | 16mm/22mm /32mm |

| TTV | <3µm |

| BOW | -30 |

| WARP | <40µm |

| Surface Type | Single Side Polished(SSP) /Double Sides Polished(DSP) |

| Polished side Ra | <0.5nm |

| Back Side Criteria | General is 0.2-0.5µm or as customized |

| Edge Criteria | R=0.2mm or Bullnose |

| Optical doped | Zn/MgO etc. |

| Wafer Surface Criteria | |

| Particles @>0.3 µm ≤30 | |

| Scratch , Chipping None | |

| Defect No edge cracks, scratches, saw marks, stains | |

| Packing | 25pcs per box |

SAW Grade Lithium Tantalate Wafers

| Parameter | Specification |

| Material | LiTaO3 wafers |

| Diameter | 3inch/4inch/6inch |

| Diameter Tolerance | ±0.03mm |

| Curie Temp | 603±2℃ |

| Cutting Angle | X/Y/Z/X112Y/Y36/Y42/Y48/etc. |

| Tol(±) | <0.20 mm |

| Thickness | 0.18 ~ 0.5mm or more |

| Primary Flat | 22mm /32mm /42.5mm /57.5mm |

| LTV (5mmx5mm) | <1µm |

| TTV | <3µm |

| BOW | -30 |

| WARP | <40µm |

| PLTV(<0.5um) | ≥95%(5mm*5mm) |

| Orientation Flat | All available |

| Surface Type | Single Side Polished(SSP) /Double Sides Polished(DSP) |

| Polished side Ra | <0.5nm |

| Back Side Criteria | General is 0.2-0.5µm or as customized |

| Edge Criteria | R=0.2mm or Bullnose |

| Wafer Surface Criteria | |

| Contamination None | |

| Particles @>0.3 µm ≤30 | |

| Scratch , Chipping None | |

| Defect No edge cracks, scratches, saw marks, stains | |

| Packing | 25pcs per box |